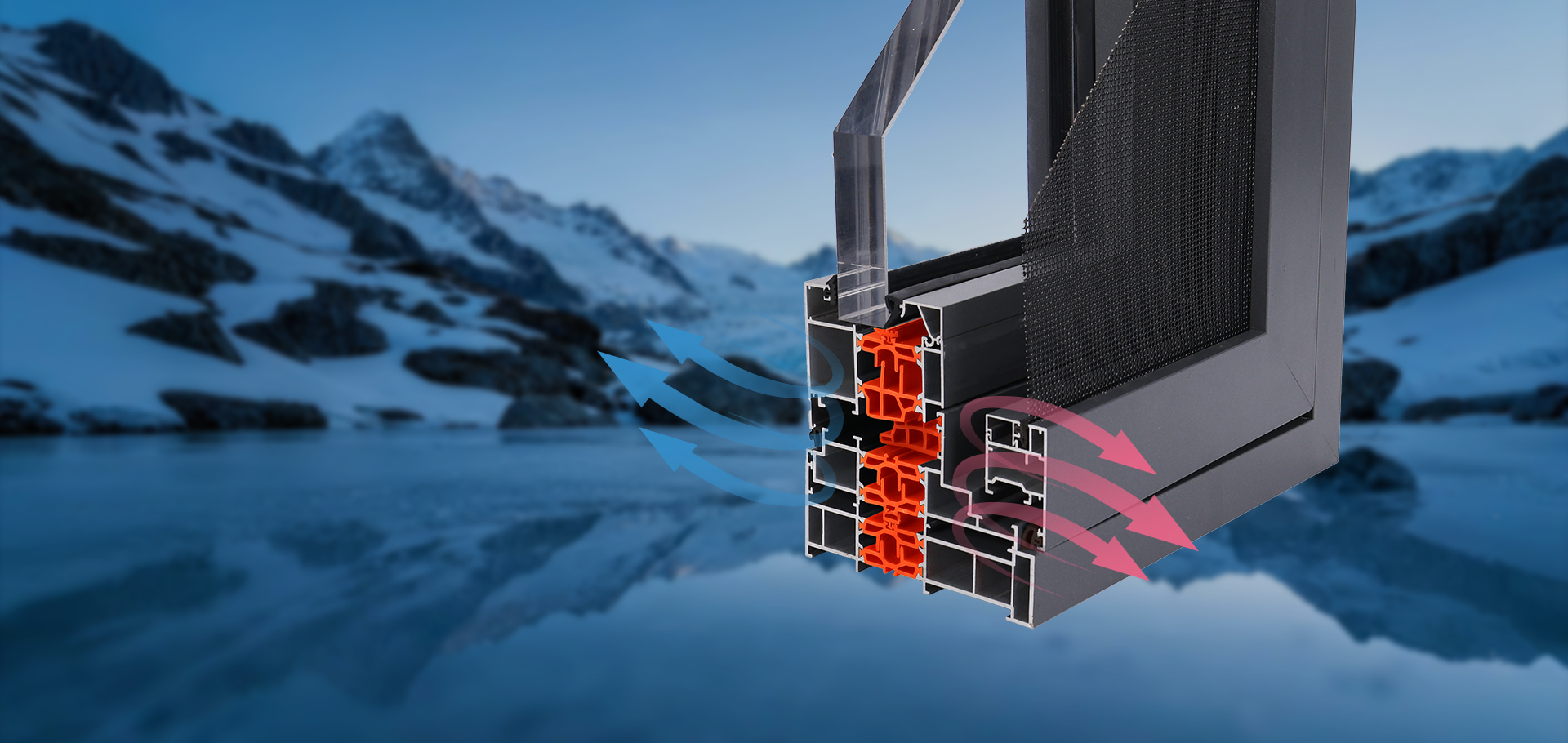

Thermal barrier strips are widely recognized for their role in improving the thermal performance of aluminum window, door, and curtain wall systems. However, focusing solely on insulation significantly understates their broader engineering value. In modern building envelopes, nylon-based thermal barrier strips play a critical structural role , contributing to mechanical stability, durability, system integrity, and long-term performance under complex environmental conditions.

Structural Continuity and Load Transfer Capability

One of the most important structural advantages of nylon-based thermal barrier strips lies in their ability to maintain load transfer continuity between interior and exterior aluminum profiles . Although thermal breaks physically separate metal sections, they must still transmit mechanical loads such as wind pressure, glazing weight, and operational forces .

High-performance nylon materials, typically reinforced with glass fibers, exhibit excellent tensile and flexural strength , allowing the thermal barrier strip to function as a load-bearing connector rather than a passive insulating insert . Properly engineered strips distribute stress evenly across the profile interface, reducing localized stress concentrations that could otherwise lead to deformation or fatigue failure.

Compatibility with Differential Thermal Expansion

Aluminum expands and contracts significantly under temperature changes, and uncontrolled differential movement can compromise frame integrity . Nylon-based thermal barrier strips offer a critical advantage through controlled thermal expansion behavior that closely matches aluminum.

Because the coefficient of thermal expansion of reinforced nylon is more compatible with aluminum , both materials expand and contract in a synchronized manner. This reduces internal stress, preserves alignment, and maintains long-term dimensional stability , even under repeated thermal cycling or intense solar exposure.

Resistance to Creep and Long-Term Deformation

In facade systems, components are subjected to continuous mechanical loading over long service lives , making creep resistance a key structural requirement. Nylon-based thermal barrier strips, when properly formulated and reinforced, demonstrate high resistance to creep and permanent deformation .

This ensures that mechanical engagement, glazing pressure, and sealing interfaces remain stable over time , preventing performance loss caused by slow material deformation. As a result, structural reliability and insulation performance are preserved throughout decades of operation.

Contribution to Frame Rigidity and Impact Resistance

Beyond static loads, window and curtain wall systems must withstand dynamic forces such as wind gusts, vibration, and operational impacts . Nylon-based thermal barrier strips contribute to overall frame rigidity , acting as a stabilizing core between aluminum sections.

Their inherent toughness provides enhanced impact resistance and vibration damping , reducing stress transmission and improving the structural resilience of the frame. This also contributes indirectly to improved acoustic comfort and reduced fatigue-related damage .

Moisture, Corrosion, and Environmental Resistance

Structural durability is closely tied to environmental resistance. Nylon-based thermal barrier strips offer strong resistance to moisture absorption, chemical exposure, and UV degradation , helping protect adjoining aluminum components.

By limiting moisture penetration at the metal interface, these strips reduce corrosion risk and preserve the structural integrity of aluminum profiles , especially in humid, coastal, or polluted environments where facade degradation is accelerated.

Structural Performance Comparison

| Structural Property | Reinforced Nylon Thermal Barrier | Non-Reinforced Polymer Insert |

| Tensile strength | High | Moderate to low |

| Load transfer capability | Excellent | Limited |

| Creep resistance | High | Moderate |

| Thermal expansion compatibility | Well matched to aluminum | Poor to moderate |

| Impact and vibration resistance | Strong | Limited |

| Long-term dimensional stability | Excellent | Variable |

Integration with Complete Façade Systems

Another key structural advantage is precision integration with complex aluminum profiles . Nylon-based thermal barrier strips can be extruded to tight tolerances, ensuring consistent mechanical engagement and reliable assembly .

Because these strips perform both insulation and structural connection functions , they enable slimmer profile designs without sacrificing strength—supporting modern architectural aesthetics while maintaining engineering reliability .

While thermal insulation is a primary function, nylon-based thermal barrier strips deliver substantial structural advantages that extend far beyond heat control. Through load-bearing capability, creep resistance, thermal compatibility, impact toughness, and environmental durability , they serve as integral structural components within high-performance aluminum window, door, and curtain wall systems.

From an engineering perspective, these strips should be evaluated not as accessories, but as critical contributors to long-term structural integrity and system reliability across the entire building lifecycle.